Tailored

Test Solutions

test services climatic chambers environmental chambers durability testing climatic testing vibration testing data acquisition test consultancy tensile test machines Lloyd LRX Instron MTS Sanwood Salt spray chamber rain chamber tts tts tts strain gauging vibration testing shaker testing durability testing mechanical testing salt spry HAST chamber 3D printing Test 3D Print 3d PLA ABS how to test 3d printed parts mechanical testing of 3d parts additive manufacturing Lloyd EZ50 500kN WCAC Testing Water charge air testingLDS V721 shaker ozone calibration

Tailored Test Solutions Ltd

Data Acquisition

At TTS we understand that accurate testing and/or analysis can only be achieved with knowledge and understanding of the inputs the product is subjected too. This is valid whether it is a complex sub-assembly, complete vehicle or even just a simple bracket or fastener.

Data acquisition is an essential part of understanding the product and the conditions in which it operates. The data generated can be invaluable to the design engineer to further their understanding of product performance and potential failures. The data can also be used to optimise product design in terms of cost and weight etc.

From 1 To 100+ Channels. We have the equipment and experience to collect data in the lab, Proving Ground, and in service – anywhere.

Our data acquisition team has collected data in many locations around the world and has encountered extremes of environmental conditions.

Recent projects:

-

-

Ultra high end sports car, full data collection exercise 100+ channels

-

Armoured Military support vehicle, full data collection exercise 100+ channels

-

Rail components including anti-roll bars and bushes etc.

-

A4 Bittern Steam Locomotive Pacific Class. Data collection to establish safe running at 90mph

-

TTS engineers collect data around the world. Locations include; UK and European proving grounds, Russia, Czech Republic, Romania, Poland, Singapore, Korea, Germany.

For automotive activities our specialist RLD (Road Load Data) team includes highly trained test drivers, who are all high speed and skid pan trained with many years of test track experience.

Vehicles tested have ranged from small electric vehicles (EV’s) to large armoured military vehicles.

TTS were tasked with collecting data on the digging mechanism of this military support vehicle. We were brought in after the first contractor had over-run on budget and still not acquired suitable data. The data we acquired was used to optimise the design and perform a durability test on a rig in house. After successful completion of the RLD exercise TTS engineers were also asked to help on the durability test.

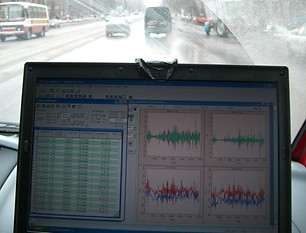

TTS engineers performing a data collection exercise in Russia using Wheel Force Transducers, accelerometers and displacement sensors on all four wheels.

This vehicle was driven across Europe to the proving grounds in Russia.

The data was then analysed using Glyphworks to compare test schedules from other international markets and to produce durability rig drive profiles.

TTS engineers have experience of using both MTS and Kistler WFT’s .

One of the more unusual data collection exercises TTS has completed was on the Bittern Pacific class steam locomotive. To celebrate the anniversary of the Mallard world record our customer wanted to run the Bittern at 90mph. Railtrack needed reassurance that the locomotive would not unduly stress the tracks at such a high speed. TTS instrumented the locomotive and then in the the middle of the night we collected accelerations from the bogeys and body and used these in the analysis of the data presented to Railtrack.